8 3 Cummins Injection Pump Timing

The following information is found on the ecm dataplate.

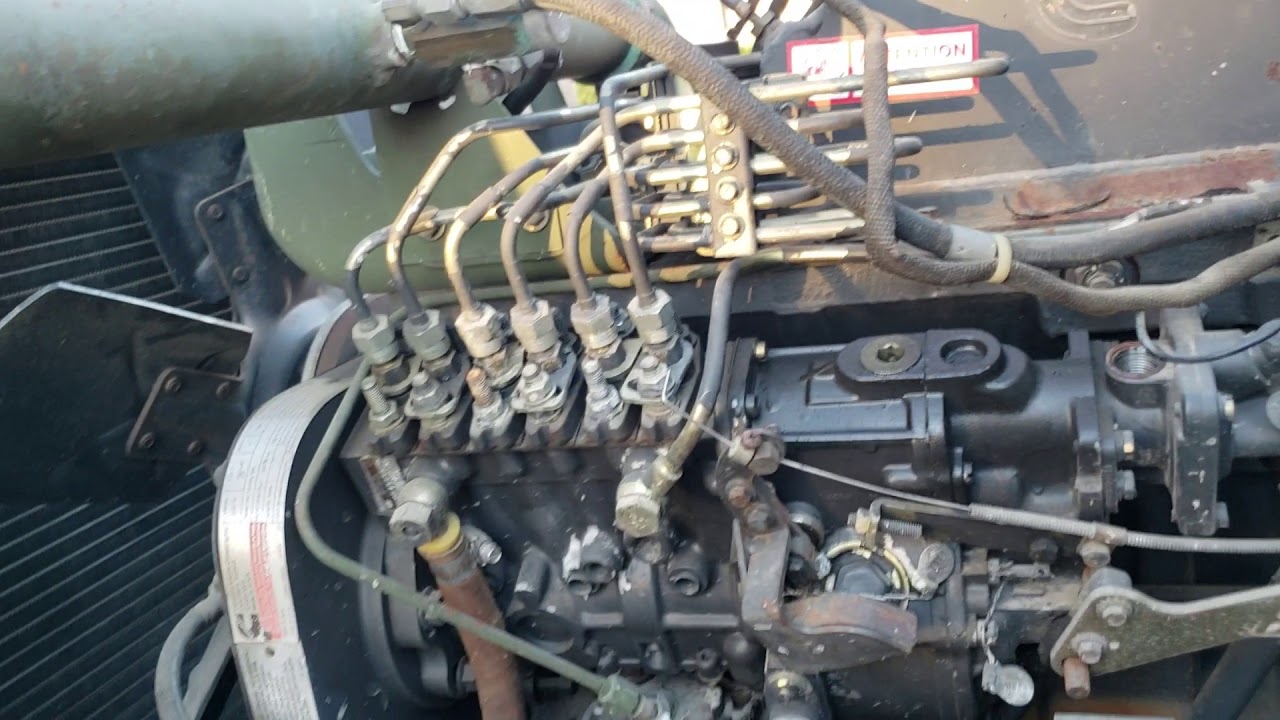

8 3 cummins injection pump timing. But how much power. Some of the most common ways to advance the timing are. Fuel injection pump dataplate the cummins accumulator pump system caps fuel injection pump dataplate is located on the side of the injection pump. Pin timing a p7100 pump off the engine.

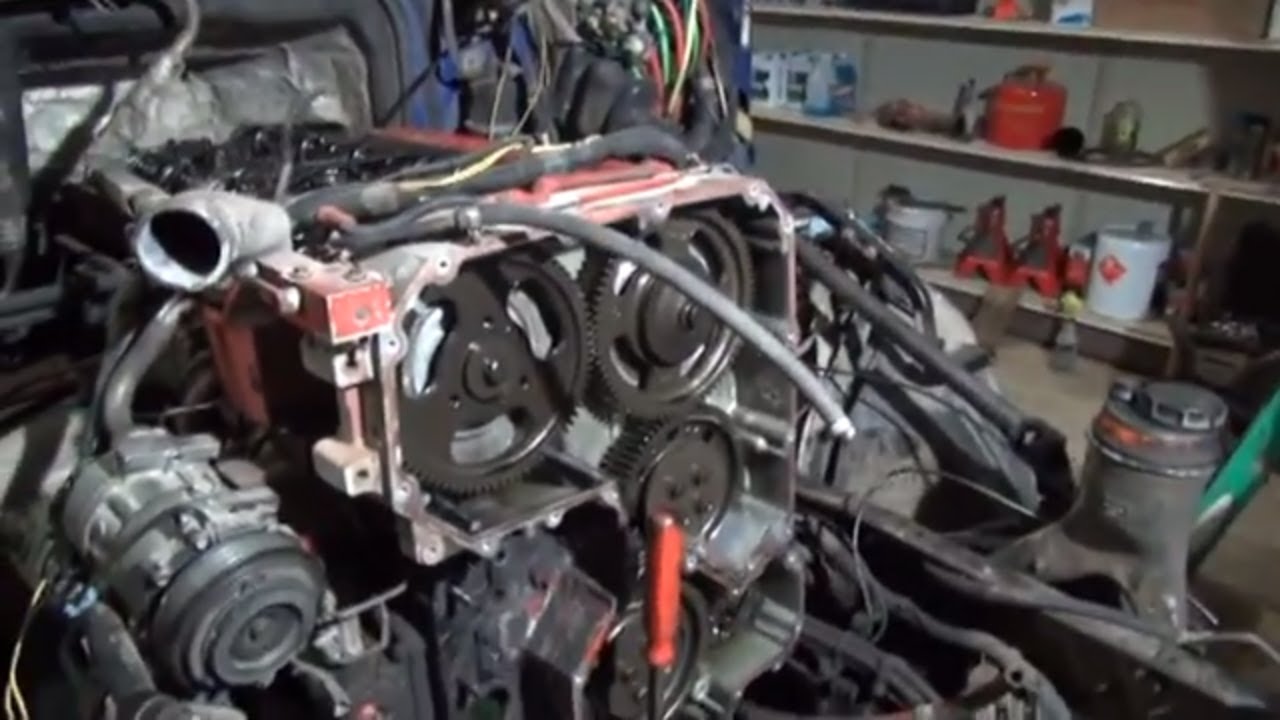

We hear it all the time timing makes power. The engine control module is a computer that analyzes information to control your. Before making any adjustments make sure the cold start cable is in and the camshaft drive belt has proper tension. This means with both the cam pin engine tdc and injection pump timing pins pushed in the advance will be 8 degrees as that is a function of ip pump setup.

Install and tighten the fuel injection pump retaining nut. This is not the final torque value for the retaining nut. If the timing tooth is not aligned with the timing pin hole rotate the fuel injection pump shaft until the timing tooth aligns. How you adjust the injection timing of the injection pump also depends on the type of marine engine you have and its age.

In our last. Our 6cta8 3 engines are timed at 8 degrees per the data tag. Ecm dataplate qsc8 3 and qsl9 engine identification section e engine and system identification page e 3 ecm dataplate the ecm dataplate is located on the front of the ecm. Jason sands 2020 05 12 cummins diesel engines diesel tech how to.

Engine was dissembled when gived to me and the marks given to me. Well there are a number of variables but it was a question we decided to try and answer with our pretty much stock 12v p pump cummins project green monster. It is in a 1995 ford f750 5 yard dump. 12 degrees of timing to 18 degrees how much will we gain.

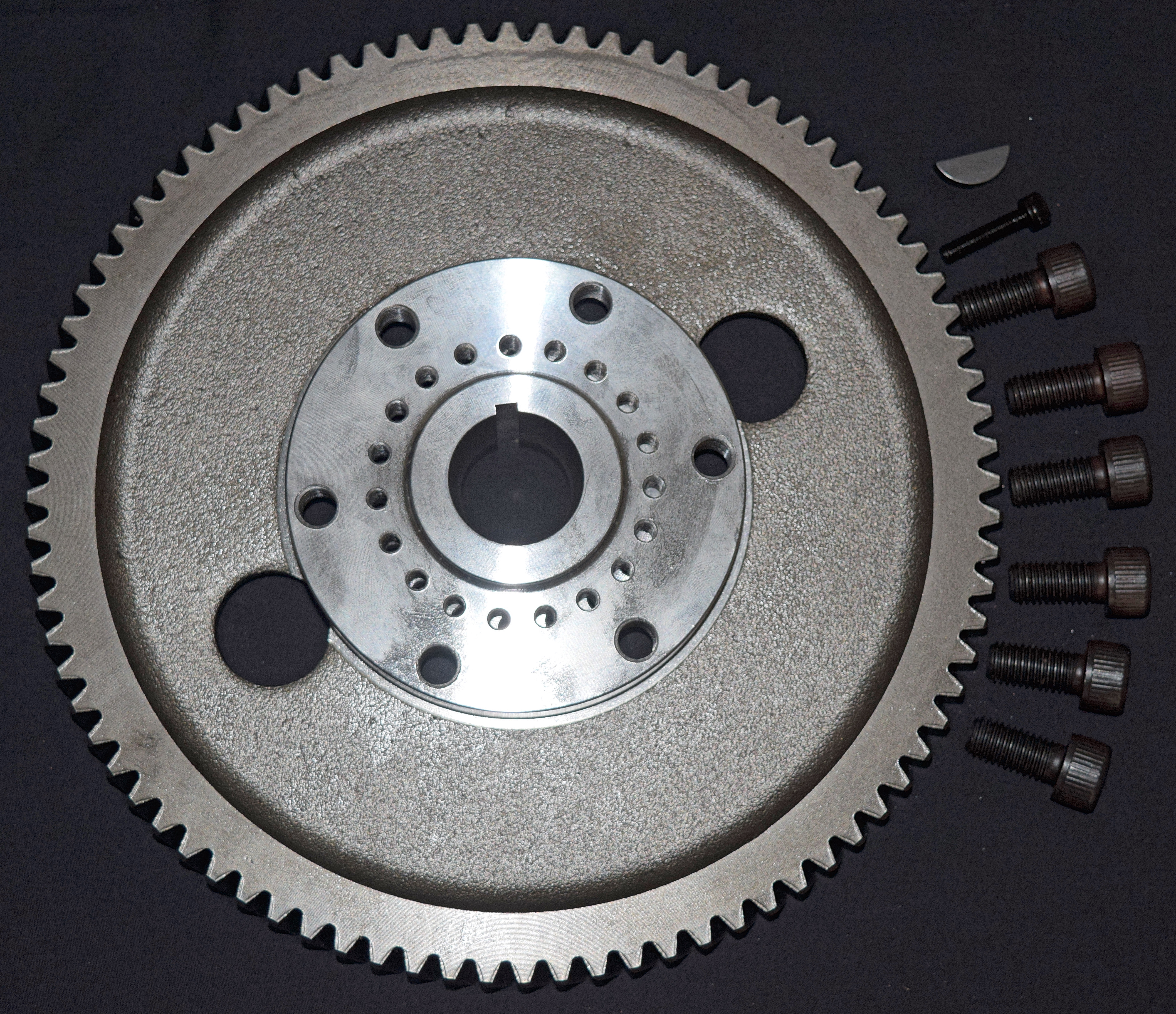

But the ip driven gear is adjustable as it is a tapered fit like a lawnmower engine flywheel sans key way me thinks.